Palm oil is one of the most widely used vegetable oils. The low-cost product is used in many sectors of the food industry and can also be used in the production of biofuels.

However, palm oil production has far-reaching ecological consequences: Large areas of tropical rainforest are being cleared to enable the planting of palm tree monocultures, resulting in the loss of valuable ecosystems and severely impacting biodiversity. For example, this poses a serious threat to the orang-utan population on the Indonesian islands of Borneo and Sumatra. In addition, the palm oil produced in the tropics needs to be transported over very long distances to consumers in Europe and the USA, with corresponding consequences for the environment. The use of palm oil for biofuels also competes with food production.

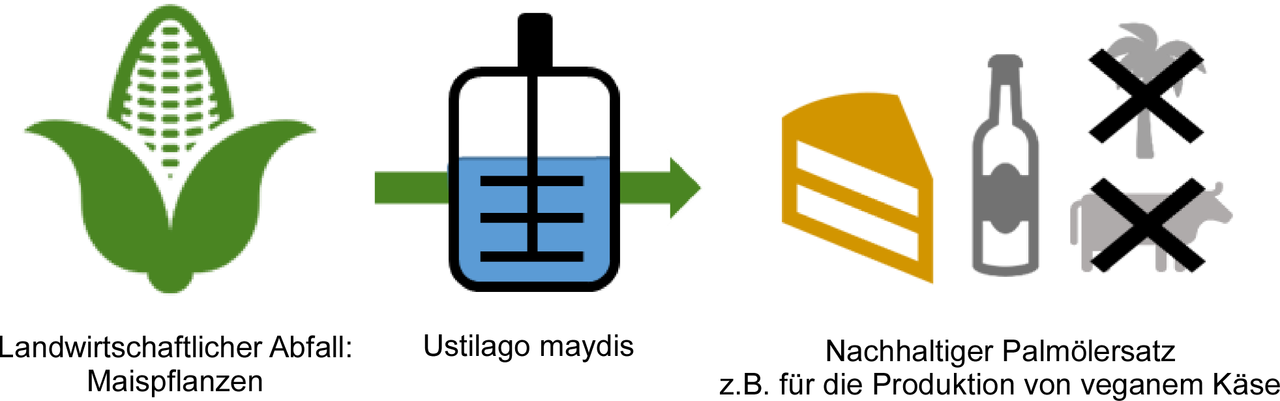

It would be significantly more sustainable, resource- and eco-friendly to produce a product similar to palm oil on a regional basis near to consumers – from plant residues that cannot be used cost-efficiently either as food products or as chemical raw materials for industry. This is exactly the objective being pursued by the NextVegOil research consortium based in North Rhine-Westphalia (NRW).

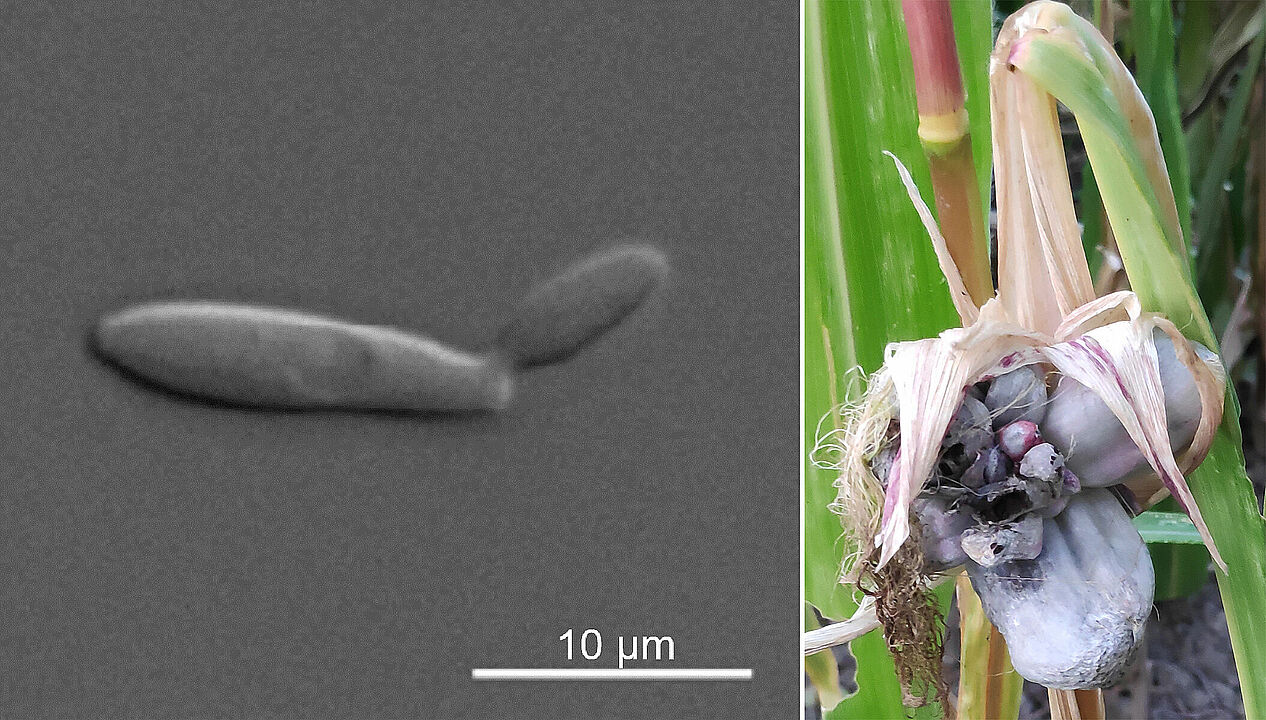

Using the fungus Ustilago maydis, the researchers have found a way to produce a microbial oil which closely matches palm oil – i.e. it has a similar composition of fatty acids, which determine its properties – meaning that it is likely to be suitable for use in food. In the course of the project, the aim is to establish the fermentation of corn stover – which cannot be eaten or used as animal feed – on a large scale.

The agricultural industry is not well-disposed towards Ustilago maydis otherwise: The unicellular fungus causes the plant disease “corn smut”; this fungus is however harmless to humans and is even considered a delicacy in Mexico. “While it is a disadvantage for some, we can utilise it to achieve our goals: As the fungus is so well adapted to corn, it is also ideally suited to recycling corn residues,” says Professor Dr Michael Feldbrügge from the Institute of Microbiology at HHU, who is one of the researchers involved in the project in Düsseldorf. He continues: “There has already been a significant amount of genetic and biotechnological research into the fungus, which naturally also produces other biotechnologically relevant substances such as biosurfactants, so we know where we can use it for our purposes.”

Professor Feldbrügge’s colleague, Professor Dr Markus Pauly from the Institute of Plant Cell Biology and Biotechnology at HHU, adds: “Corn also offers breeding potential in terms of optimising the plant residue for this kind of metabolic transformation by the fungus without transgenic methods.”

The researchers have found out that Ustilago maydis can also produce oil instead of surfactants if the synthesis process of the fungus is interrupted at a specific point at genetic level. This has already been demonstrated on a small scale. The fatty acid profile of this oil is very similar to that of palm oil, making it highly promising as a substitute product. In the next few years, the researchers in Düsseldorf are aiming to optimise the fungus so that the oil it produces matches the properties of palm oil even more closely. They are also working on biotechnological processes to ensure optimum conversion of the corn stover raw material in the fermenter.

The project partners at Aachen University of Technology (RWTH) are working on the next steps towards establishing an economically feasible production process for the palm oil substitute. Once the optimum parameters for the corn biomass conversion and the fungus have been found in Düsseldorf, it will be possible to move on to implementing the fermentation process on a commercial scale. The oils produced in this microbial process must then be precisely analysed and purified to ensure they meet food standards.

In addition to the biological and technical aspects, there is also an economic aspect: In parallel with the ongoing activities, researchers in Bochum are analysing the cost-efficiency of the process chains and investigating the markets on which the palm oil substitute can be sold. Piloting the product is the focus of project partner Formo, a biotech start-up, which aims to produce vegan cheese using the microbial oil.

“It is important to everyone involved in the project that we can offer a sustainable product as an alternative to conventional palm oil: a regional product, made from renewable raw materials, with a good carbon footprint. And also a product which does not compete with food production, as the starting materials are residues that are generated anyway,” emphasise Professor Feldbrügge and Professor Pauly.

The NextVegOil project

The project for the microbial production of a palm oil substitute will receive funding of around 1.1 million euros in total from the BioSC over the next three years. Two biology institutes at HHU are involved: The Institute of Plant Cell Biology and Biotechnology (Professor Dr Markus Pauly) and the Institute of Microbiology (Professor Dr Michael Feldbrügge) are working on the optimisation of the corn biomass, its conversion using Ustilago maydis and the optimisation of the oil production.

The Chair of Biochemical Engineering at RWTH Aachen, headed by Professor Dr Jochen Büchs, is concentrating on the fermentation of the oil. At the University of Münster, researchers at the Institute of Inorganic and Analytical Chemistry led by Professor Dr Heiko Hayen are analysing the composition of the oils produced. Professor Dr Stefanie Bröring from the Chair of Entrepreneurship and Innovative Business Models at the Ruhr University Bochum is examining the economic and marketing aspects. Finally, the biotech start-up Formo, based in Berlin and Bonn, is aiming to use the palm oil substitute for the production of vegan cheese.

Bioeconomy Science Center (BioSC)

The bioeconomy comprises all economic sectors aimed at the production, processing and use of biological resources – plants, animals, microorganisms – including e.g. the production of foodstuffs and animal feed, the provision of biomass as a raw material and the production of bio-based chemicals/materials and bioenergy. The goal of the BioSC, established by the universities in Aachen, Bonn and Düsseldorf together with Jülich Research Center, is to create the foundations for a knowledge-based bioeconomy by supporting the excellent research landscape in North Rhine-Westphalia and connecting it with the strong bioeconomy-oriented industrial environment to establish a single integrative approach.

Further information: BioSC's website